Your shipping setup hugely impacts your profit margins, customer experience, and repeat purchase rate. Here's how to do it right!

New ecommerce stores might underrate shipping, believing it's just a box to check after setting up everything else. However, your shipping setup hugely impacts your profit margins, customer experience, and repeat purchase rate.

In this blog post, you'll find easy and step-by-step guidance on the most important aspects of e-commerce shipping. By the end of it, you'll have a better understanding of the shipping process and its value.

Let’s go!

Step 1: Define Your Shipping Strategy

When defining your shipping strategy, you should consider the price range of your products, the volume of your orders, the typical destinations you ship to, etc.

Put simply, there are 3 main options:

Option #1: Flat Rate

Same shipping fee no matter what. This option is simple, easy to calculate, but it can lose you money on heavy orders or discourage light ones.

A personal example to back this up: I recently wanted to purchase a skirt that cost $15. The shipping was $20, as this retailer had a flat rate. I reached out and asked if there was another shipping option, but they said there wasn't. I eventually didn't proceed with my order because it seemed ridiculous to pay more for shipping than for the product.

Option #2: Free Shipping

Customers looooove it! However, to justify free shipping, you definitely need to offset it elsewhere.

The most common offset practice is to set up a minimum order value, which often boosts the final cart value. Brands offering free shipping with a $50–$75 threshold often see a 10–30% increase in average order value. But only if margins can absorb $6–$12 per shipment. Run the numbers before making it your default.

You can also incorporate shipping costs into product prices or negotiate discounts with carriers, especially if your e-commerce store is big enough to have huge volumes of orders.

Option #3: Real-Time Rates

This means that, at checkout, your website pulls live quotes from carriers. This option is precise, but can create frustration if prices fluctuate, especially for returning customers who expect a certain amount that has eventually changed.

Step 2: Choose Your Fulfillment Model

To choose your fulfillment model means to decide how orders will get from your store to your customer.

You’ve got three core options:

| Model | Control | Cost | Scalability | Complexity |

|---|---|---|---|---|

| Self-fulfillment | High | Low (at low volume) | Low-Medium | High |

| 3PL (Third Party Logistics) | Medium | Medium | High | Medium |

| Dropshipping | Low | Low upfront | High | Low (but thin margins) |

You can also check out this detailed article that compares self-fulfillment and 3PL.

Let’s break each one down:

1. Self-Fulfillment (aka "do-it-yourself")

You store, pick, pack, and ship orders yourself. Best suited for early-stage businesses or those selling handcrafted or luxurious products, or having low-volume orders.

Pros:

- Full control over packaging, speed, branding, and customer communication

- No 3PL contracts or minimum volume commitments

- Easier to offer personalized touches (e.g., handwritten notes, samples)

Cons:

- It's labor-intensive and requires upfront cost for fleet, driver, etc

- Hard to scale beyond ~30–50 daily orders without staff or warehouse

- Shipping costs are typically higher

2. Third-Party Logistics (3PL)

With 3PL, you outsource warehousing and fulfillment to a logistics provider like FedEx, UPS, USPS, etc. You send them inventory, and they handle the rest.

Pros:

- Faster shipping via distributed warehouses (get closer to customers)

- Access to discounted carrier rates through the 3PL

- Scales smoothly as order volume grows

Cons:

- Less control over packaging and fulfillment times

- Setup costs, integration, and storage fees

- Service quality varies—vetting is critical

If most of your customers are in 3–4 key metro areas (e.g., NYC, LA, Chicago), using a 3PL with multiple fulfillment nodes can reduce average shipping cost by up to 30% via zone reduction. Many sellers don’t factor in how much zone-based pricing affects profitability.

3. Dropshipping

You sell the product, but a third party (usually a manufacturer or wholesaler) ships directly to the customer.

Pros:

- No inventory risk

- Minimal startup cost

- Easy to test products without commitment

Cons:

- No control over inventory, shipping speed, or packaging...or basically anything

- Customer service issues fall on you, even when delays aren’t your fault

- Often razor-thin profit margins (10–20% typical)

The bottom line is that your fulfillment model should match your product volume, cash flow, and customer expectations. Start where you are—but plan ahead for scale.

Step 3: Set Up Carrier Accounts (And Negotiate)

Not all shipping labels are priced equally. Here's a rough break down of your options:

- USPS: Best for small, light packages. Reliable and cost-effective under 1 lb.

- UPS/FedEx: Better for heavier packages and guaranteed delivery windows.

- Regional Carriers: Fast and affordable but limited to specific areas.

An overlooked factor is that carriers use dimensional (DIM) weight pricing—you may pay for the space a package takes up, not just its actual weight. Sometimes a 3 lb pillow might cost more to ship than a 10 lb blender.

Once you hit ~100+ monthly shipments, you can negotiate discounted rates or use a 3PL’s pre-negotiated rates. A typical discount might reduce a $12 UPS Ground shipment to $8.60.

Step 4: Set Delivery Expectations & Policies

Shipping is part of your brand promise. Poor communication, delays, failed deliveries, etc, is what drives most delivery complaints.

Your goal is to set clear expectations, meet them, and reduce support touchpoints.

Here are a few key things to implement:

- Checkout Clarity: Specify shipping windows by method (e.g., “Economy: 5–8 days,” “Express: 2 days”) and include fulfillment times if processing takes more than 24 hours.

- Tracking Updates: Look for carriers that send emails or SMS at each stage—“dispatched,” “in transit,” “out for delivery,” and “delivered.” This transparency significantly reduces WISMO calls. If you're not outsourcing to 3PL companies but delivering yourself, consider implementing a software that allows you to send such customer notifications.

- Delivery Confirmation Policies: For high-value items, clarify whether you require a signature, offer delivery scheduling, or use photo proof.

According to Narvar, 83% of shoppers expect regular communication about their order, and brands that send at least three post-purchase messages see 18–22% fewer delivery-related support tickets.

Step 5: Measure and Optimize

Once shipping is up and running, the question becomes: Is it working efficiently?

Avoid vanity metrics like “shipping volume.” Instead, measure operational impact and customer experience.

Core metrics:

- Shipping Margin per Order: Not just shipping cost, but the delta between what you charge for shipping vs. what you pay. Many brands lose money by undercharging or offering free shipping without adjusting AOV or pricing.

- Delivery Reliability: Track on-time rate by carrier and service type. Anything below 95% on standard shipping warrants a review of your carrier mix or warehouse handling times.

- Support Load per 100 Orders: A rise in WISMO tickets, delivery complaints, or return issues indicates deeper problems in your process or communication.

Optimization Tactics:

- Carrier Performance Audits: Compare average delivery time, reliability, and cost per zone every 3–6 months. Route lower-performing zip codes to regional carriers.

- A/B Test Free Shipping Thresholds: See how changing a threshold from $50 to $60 affects AOV, margin, and conversion.

- Zone-Based Packaging Adjustments: If you're overspending on DIM weight, consider smaller packaging or vacuum-sealing to reduce cost.

Closing Thoughts

Before committing to a shipping strategy, you should carefully consider the pros and cons of each option, along with your business model, customer profile, and order volumes. But even if you don't get it right the first time, you can improve it.

Shipping setup isn’t a one-time decision—it’s a key part of your entire business plan. While it's costly and tedious to change your shipping strategy, sometimes it happens. Not to mention, the shipping strategy can change as your e-commerce store scales.

But as a general rule of thumb, start lean and choose a fulfillment model, offer clear policies, negotiate with carriers or improve your process if delivering yourself, and monitor your shipping strategy efficiency.

The brands that win on shipping ship smart.

Never miss a post

You may also like…

You too can reduce costs and improve efficiency with Ufleet

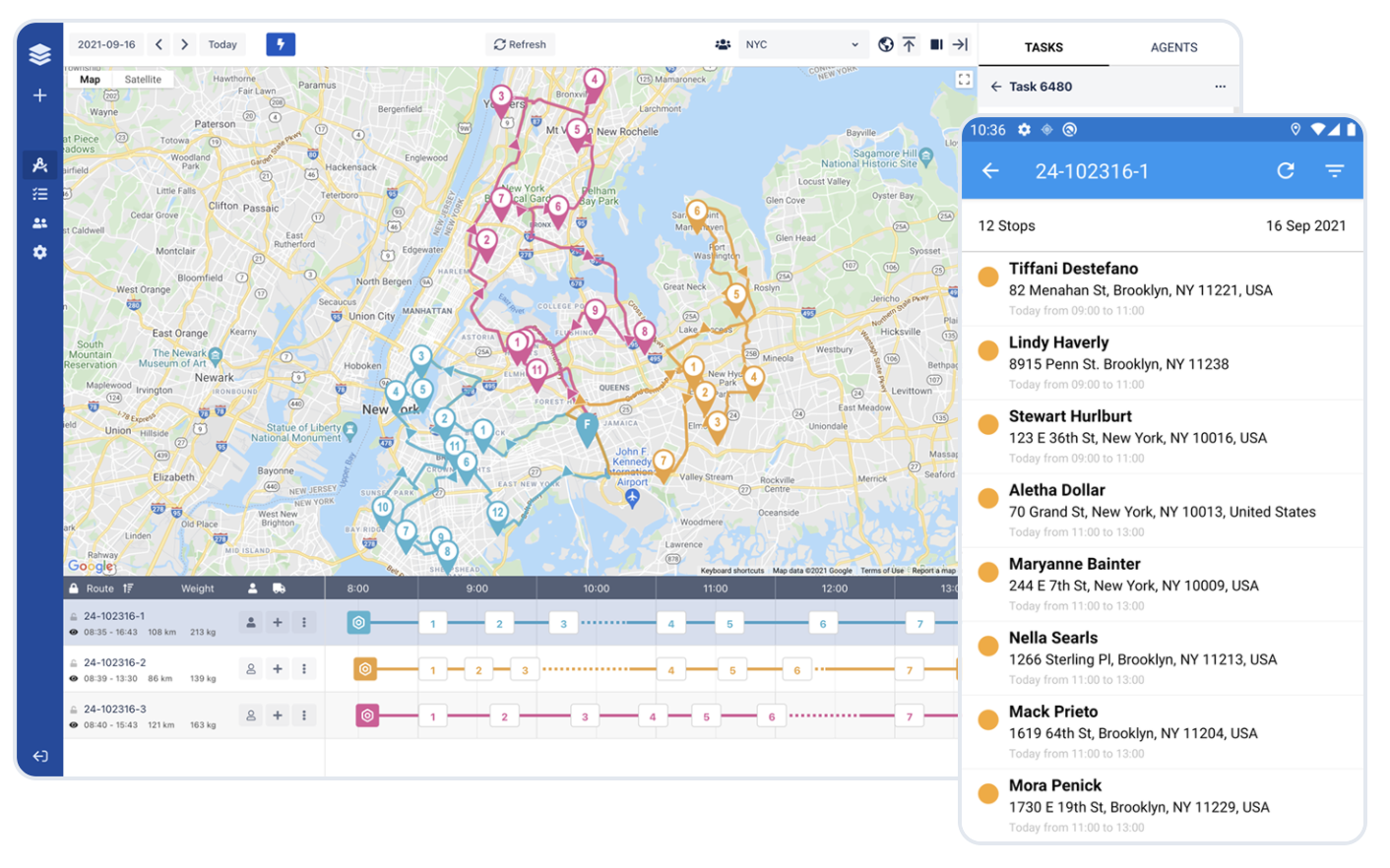

- plan and optimize delivery routes

- manage and empower drivers

- enhance customer experience

- make data-driven business decisions

We’d love to learn about your challenges.

Leave your email and we’ll get back to you.